ESG - Environment

E covers environmental factors, including climate impact, pollution, effects on water, biodiversity, logistics, and resource consumption.

At HJHansen Recycling Group, we are very aware of our environmental impact, and therefore we continuously work to minimize our influence on the environment and climate.

On this page, we delve into the theme of E – environment

We have divided the theme according to the EU’s standards for sustainability reporting. Under each standard, we present the initiatives we have worked on in 2022/2023 to achieve results in climate neutrality, reduce pollution, protect marine and natural resources, optimize resource consumption, and support the circular agenda.

Initiatives that focus on actions within:

- Climate change

- Pollution

- Water and marine resources

- Biodiversity and ecosystems

- Resource use and circular economy

Jump directly to the section that interests you

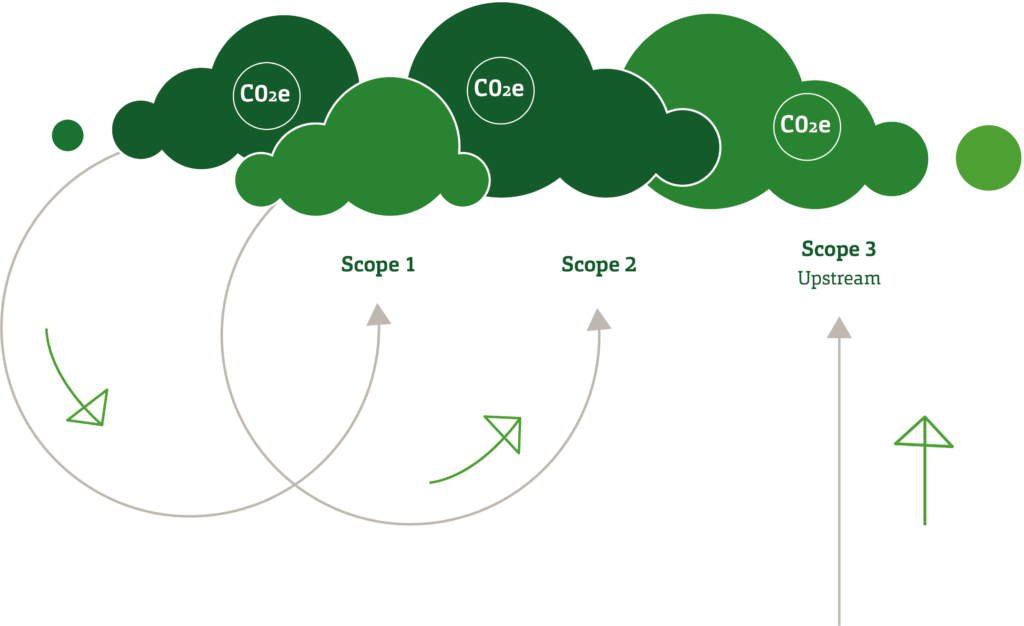

Climate accounting

At HJHansen Recycling Group, we have now mapped our Scope 1 and 2 emissions, as well as parts of scope 3, for the past three financial years with a baseline of 2020/21.

As an organization, we have increasingly improved our understanding of the frameworks for climate accounting, and many of our stakeholders are also able to engage with the data we request. There are still areas where data quality can be enhanced, but we expect this to happen as more and more companies begin their own mapping of their emissions.

Mitigation and adaptation to climate change

At HJHansen Recycling Group, we strive to minimize our negative impact on the environment by monitoring and optimizing our processes. We are certified according to ISO 14001, one of the most recognized international standards for environmental management systems, and we aim to stay ahead of developments. We have an existing climate and environmental policy.

Energy consumption and mix

All companies within the organizational boundary are classified within High Climate Impact Sectors. Below is a breakdown of the total energy consumption and energy mix of the companies.

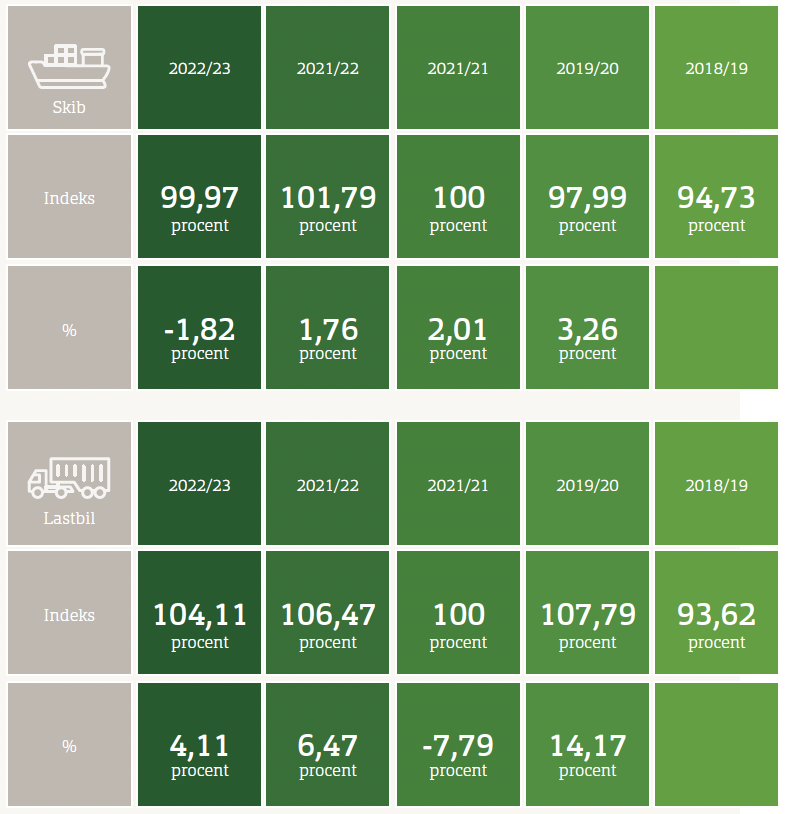

Logistics

Looking back on the past year in the logistics department, it contrasts sharply with the recent years of heated markets characterized by scarcity of all logistics forms and intense competition.

The situation has now shifted back to a more normalized market, where we can provide efficient and cost-effective logistics. This is due to the unfortunate decline in Danish and European industry.

In the logistics department, we believe that close, long-term partnerships are the way forward. Several of our hauliers have been working with us for over 25 years. They were with us during the tough times and are here now that things are easier. We have shown and continue to show understanding for the significant fluctuations and situations.

This good, close cooperation extends not only to the hauliers but also to their drivers, with whom we have daily and personal interactions. We believe that the drivers working for us are responsible and can largely manage the routes and tasks we assign to them. This is a crucial component of our entire setup – both when the market rises and falls.

A look back and forward in logistics

“It is precisely the close cooperation with the drivers and our personal contact with suppliers that allows us to once again keep the level of fruitless trips to an absolute minimum of 0.27%.

I believe we are facing a challenging future, with the market becoming even more pressured due to decreasing activity. Therefore, we have a significant task ahead to adapt our individual logistics setups to the new conditions, in collaboration with our partners.

Our advantage is that we are very agile in our approach to potential sales markets and operate in Europe, Turkey, and the Far East. Our many port locations in Denmark enable us to use all forms of transport effectively and choose the most optimal option for each task.

Since 1996, we have had port space at Aalborg Port, but with the new space, we are expanding to also be able to handle deep-sea shipments of up to 30,000 tons.”

– Rasmus Skou Oldenborg, Logistics Director

Electrification

At HJHansen Recycling Group, we have the ambition to electrify our vehicle fleet. By the end of this financial year, electric and hybrid vehicles made up 24% of our total fleet of leased company cars.

Future company vehicles will also need to be electrified, although with the provision that some of our consultants may require a traditional car due to long distances, which is why our goal is a 90% electrified vehicle fleet.

We have started installing charging stations at our sites. At the headquarters in Odense, we have established six charging points this year, but we are prepared for 18, as we anticipate an increase in electrification not only of company cars but also among employees with electric vehicles. We will need increased capacity in the future. The charging stations we set up at our locations with public parking spaces will also be available for public use.

Goal for the share of electric vehicles in the fleet from now until 2027

%

2023/24

%

2024/25

%

2025/26

Pollution

Pollution impacts our daily operations in a variety of ways.

We affect the following forms of pollution:

Impact

In our daily operations, we maintain a continuous focus on preventing pollution. We achieve this through ongoing maintenance of surface coatings at our sites, keeping certain materials under cover, and ensuring that we have water collection systems in place at our locations to manage large amounts of rainfall during periods of heavy precipitation.

Climate Change

We know that the handling of iron and metal generates noise that our neighbors can hear. Around our sites, we have installed noise barriers, and we operate only within the permits granted by the authorities. However, dialogue with our neighbors remains essential, as we do not want to create unreasonable noise pollution. Additionally, we maintain ongoing communication with the Environmental Protection Agency.

Water Consumption

When we shred materials, we use water for cooling the shredder and for dust suppression.

We have initiated a procedure where we regularly inspect our sewage systems and sand filters using camera inspections to ensure their maintenance.

Our ambition is to perform these inspections every three to five years. Additionally, we have installed a buffer tank at all our sites, which can be filled during heavy rainfall to alleviate some of the pressure on the sewers.

No Water

We are working to reduce our water consumption, especially in production. The materials we handle produce dust, and during dry periods, we water our sites to minimize dust generation for our neighbors.

Additionally, we use water to cool our large shredder in Odense. We are therefore working on a project to recycle surface water at our Odense site in collaboration with water treatment experts Clearwell.

Ressource use and circular economy

HJHansen Recycling Group’s vision is to push materials as high as possible up the waste hierarchy, which is also reflected in our motto:

“We give resources a new life.”

Recycling materials is one of the most effective, tangible, and economically viable methods to decouple economic growth from environmental impact. Naturally, the most effective approach is to consume less.

Recycling resources is at the core of our business; however, we currently do not have a policy or goal specifically addressing resource use and circular economy.

Resource fraction

Driving materials as high as possible up the waste hierarchy is an integral part of our mindset, as we at HJHansen Recycling Group have always focused on recycling. We have extensive and positive experience in this area.

The fractions that fall into the two lowest tiers of the waste hierarchy – energy recovery and landfill – are now under sharper focus, and we have chosen to call them “resource fractions” to emphasize the opportunities they present.

For both landfill and incineration fractions, our goal is to minimize the quantity and convert as much as possible higher up the hierarchy when feasible. This is an ongoing process, and we are continually gaining more insights.

Quality Assurance

We are in continuous dialogue with our suppliers about the necessity of sorting. Better sorting results in cleaner fractions, which in turn leads to better recycling. If we find that we are receiving a lot of loose waste from a supplier, we engage in a deeper discussion about the issue.

We do this because loose waste—such as plastic, wood, soil, or other materials not associated with iron or metal—should be processed through their own end-of-life procedures to reach as high a level in the waste hierarchy as possible.

Cleaner inputs result in cleaner outputs, which in turn leads to cleaner recycling with less energy consumption.

Waste management

As a company, we must adhere to the Best Available Techniques (BAT) for Waste Treatment, which is a comprehensive report that outlines the techniques available for waste management based on data from a wide range of companies and details the respective emissions associated with these techniques.

This establishes a minimum standard that we must comply with. These BAT requirements will be incorporated into our environmental approval. We know that in areas where we already conduct analyses, we meet the BAT requirements that the Environmental Protection Agency will implement in our upcoming environmental approval.